Up To 99.8%

High Quality Yield

Rigorous IQC

-

Rigorous IQC

-

Advanced Test Equipment

-

Real-time AI Test at 30 Key Nodes

-

Leading Advanced Checkout Equipment

-

Solar Module

JinenU Solar delivers high-quality solar modules that stand the test by strict quality control and inspection process, stringent acceptance criteria and tight tolerance levels, striving to achieve the target of 100% production yield with high-quality solar modules.

-

4 times 100% EL detection to minimize micro cracks

-

AI inspection process to reduce artificial missed detection

-

Strict tests to acquire quality certifications

-

Rigorous supplier management system for quality control from the source

-

200+ incoming testing to prevent the inflow of defective materials

-

Advanced intelligent inspection equipment secures accurate product inspection in real-time

Rigorous IQC

JinenU Solar follows the high standard of quality control from raw material selections by way of around 200 tests, adopting a leading-edge inspection equipment for strict incoming material test according to industry standards. Only those that pass the inspection standards can be introduced. Through comprehensive and rigorous technical analysis, test, and trial production, it can be formally put into mass production.

-

8

Cell Test -

12

Solder Strip Test -

12

Bus Bar Test -

31

Glass Test -

12

EVA Test -

16

Backsheet Test -

20

Junction Box Test -

14

Frame Test

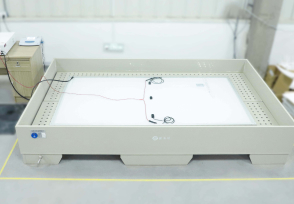

Advanced Test Equipment

The main 29 test devices were put into operation after being calibrated and qualified by authoritative institutions.

-

Crosslinking Degree Testing Equipment

-

Cell Testing Equipment

-

Horizontal Tensile Tester

-

Wet Leakage Testing Equipment

Universal Tensile Tester

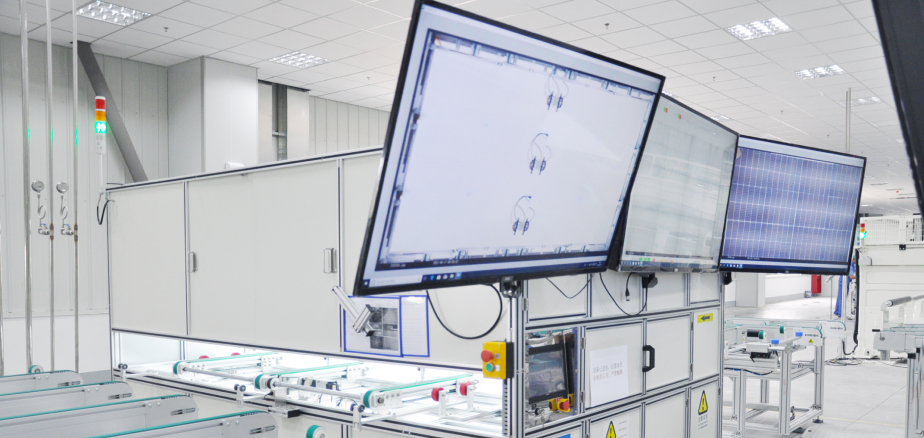

Real-time AI Test at 30 Key Nodes

JinenU adopts AI vision technology in the whole process of module manufacturing and big data platform to improve its all-round digitalization and intellectualization and optimize allocation of resources. This can guarantee a two-way improvement in production effectiveness and product quality by adopting AI vision inspection on 30 key points.

-

7

Laminating-Al inspection -

7

EL and appearance inspection before laminating-Al inspection -

7

Appearance inspection after laminating-AI inspection. -

7

EL inspection atter laminating-Al inspection -

7

Final appearance inspection-Al inspection -

7

Junction box welding-Al inspection

-

7

Size automatic measurement -

28

Automatic inspection of EL & appearance -

44

Appearance automatic identification -

18

EL automatic recognition -

76

Appearance automatic recognition -

7

Visual inspectioh for welding

Cutting-edge Inspection Equipment

The production line adopts horizontal direct photography, using imported SONY camera with 4.608 million pixels, characteristics of recognition accuracy<0.5mm/pixel and shooting time 0.5s and test time 2s/cell string, capable of AI intelligent judgment and click to enlarge, which is convenient to check the type of defects and the working status of the welding machine.

The 3A+ class light source adopted and the continuous testability of the same module ≤0.15%. Both single light source and single control system were applied to secure the synchronization of flash during the test. The software can accurately collect and calculate all parameters such as Isc, Voc, Ipm, Vpm, and light intensity.

The advanced automatic classification system, which is connected to the intelligent information processing system, can precisely classify solar modules. It can meet the grading needs of all mainstream module types in the industry. Through the automatic image positioning and recognition system, the equipment is driven by servo motor with high-speed, stable and accurate operation.

Solar Module

Fully-compatible intelligent production facilities enable customized modules to meet the diversified needs of customers. Combining 182mm and 210mm cells with MBB & SMBB technology, we provide our customers with high-conversion modules suitable for various application scenarios, and customize the modules according to the needs of our customers to adapt to different regional markets.

-

2021182mm PERC

Monofacial and bifacial modules mass production

-

2022210mm PERC

Monofacial and bifacial modules mass production

-

2023182mm TOPCon

Monofacial and bifacial modules mass production

If You have ODM|OEM Requirement, Please Contact Us

Our professional team will provide the satisfactory customized production proposal for you