Customized Project | JinenU Solar Micro-rectangular 78.6MW High Efficiency Module Project

_

Customized Project

78.6MW

Currently, the photovoltaic industry is accelerating towards high-power modules, and rectangular modules are rapidly entering the market, becoming a new breakthrough in module efficiency to meet the needs of different application scenarios.

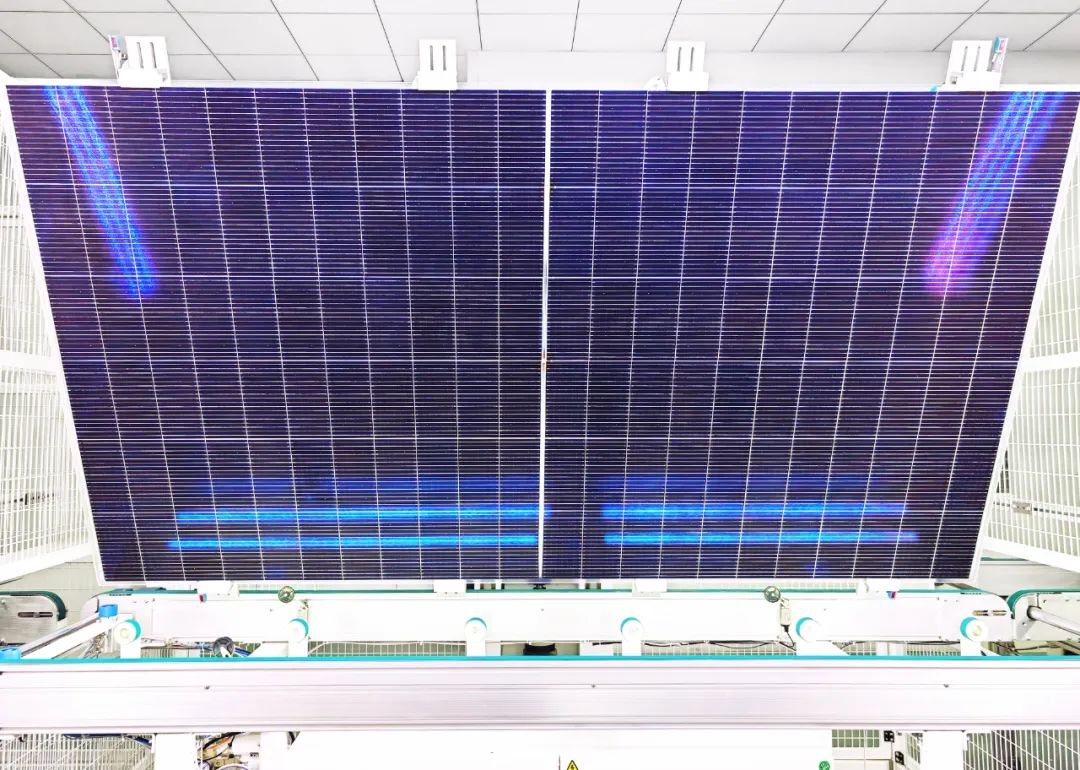

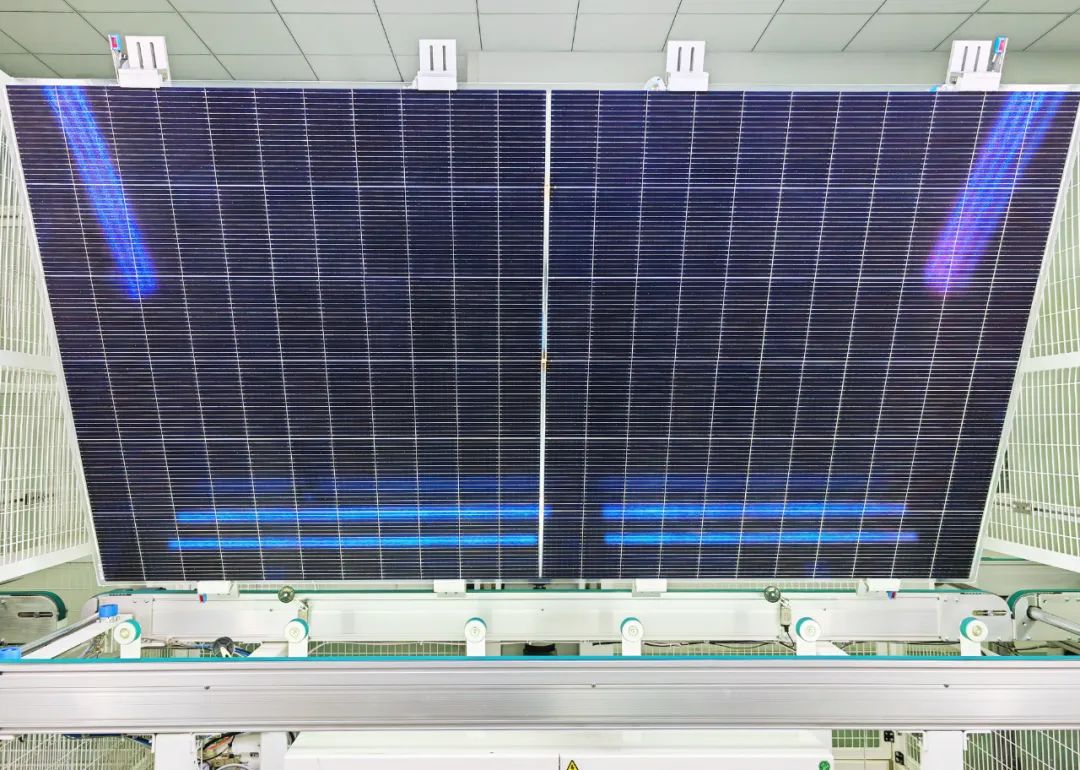

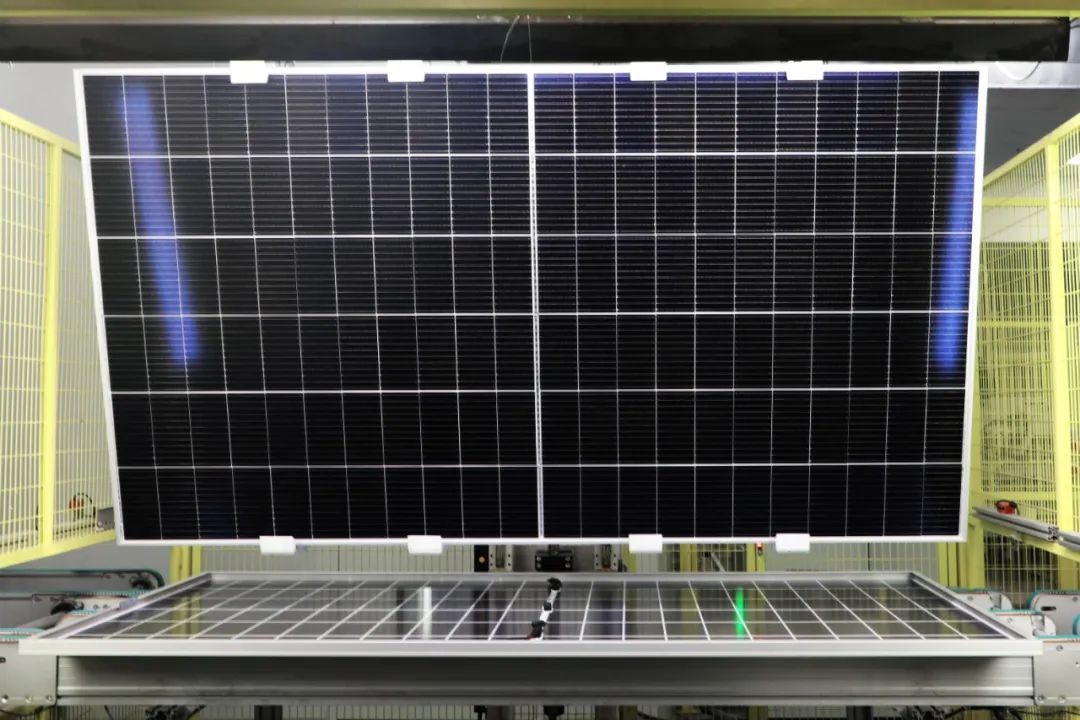

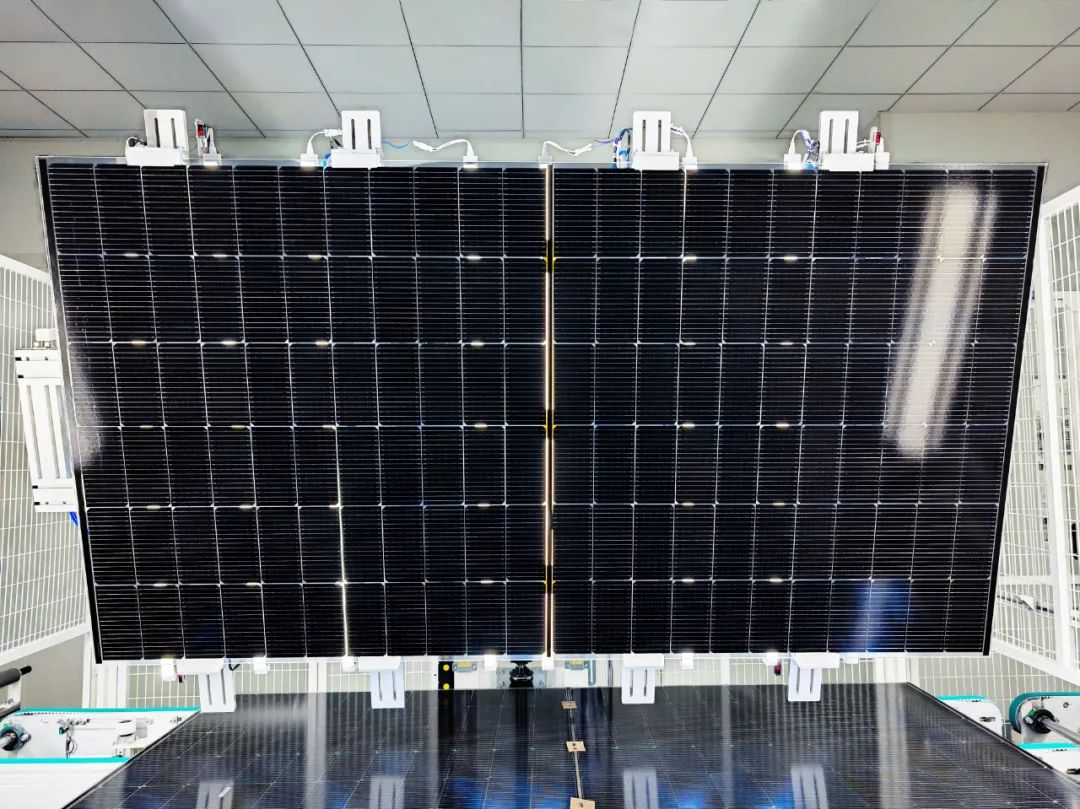

JinenU Solar received a customized ODM|OEM demand from the customer, producing 182mm 72 cells bifacial high-efficiency micro rectangular modules with a power of 555W. The total order quantity is 78.6MW, approximately 143,000 pieces.

This order is the first mass-produced customized rectangular module of JinenU Solar, and the successful mass production this time proves the strength and efficiency of JinenU Solar's customized production as well as its technical capability and production experience, and further confirms JinenU Solar's strength in meeting customers' customized demands and its ability to continuously provide customers with better quality and more competitive products and services.

● Manufacturing challenges & solutions

The overall dimensions of the 82mm*183.75mm 72 cells bifacial coated module are 2278*1134mm, using P-type 10BB multi-busbar high-efficiency solar cells, paired with 0.29mm round wire on both sides and 0.32mm tinned wire for the busbars in the middle; POE+EVA+semi-tempered textured glass, with a gap of 0.8±0.1mm between the cells. The design output power of the module can reach up to 555W, effectively reducing the shading of the cell busbars, improving optical utilization, and maximizing the use of sunlight to enhance module power, making it more advantageous in terms of performance and price.

Due to the special nature of rectangular battery cells and material pairing, higher requirements for equipment accuracy and stability, as well as stricter requirements for the capabilities of manufacturing department personnel. This order encountered edge chipping, hidden cracks in the form of the Chinese character "八", and cell merge during the trial production process. In response to these issues, the manufacturing department at the Zibo base immediately conducted in-depth analysis, assessing from multiple perspectives such as materials, design, and production processes, and formulated effective solutions. After a trial production of 50 cells and continuous tracking and improvement, by optimizing the welding machine's tab pull-up, flattening sequence, thickness, length monitoring, and lamination parameters, the problem was successfully resolved, laying a solid foundation for smooth mass production.

● Customer feedback

"We used to do regular layout in JinenU Solar, this time although it is the first time to do rectangle sheet in JingYou, and we encountered some problems at the beginning, but everyone is very experienced and solved the problems quickly, and now the yield rate is also very stable, which makes us see the strength of JinenU olar’s manufacturing once again."

MoreNews

-

2024-12-30

JinenU Solar's 7th Domestic Base To Be Located in Meishan(Sichuan Province) -

2024-12-30

JinenU Solar Tai’an Base 2-Year Anniversary Since Put Into Production -

2024-12-23

Qianshan Base Put Into Production For One Year -

2024-12-13

Media Focus | Wu Fei, Founder and Chairman of JinenU: Innovative Business Models to Realize Capacity Sharing -

2024-12-05

Tai'an Base GM Zhang Pengfei Attend the 18th China New Energy International Forum -

2024-12-02

Customized Project | JinenU 210N High-Efficiency, Large-Size 700W Module Project -

2024-11-20

Chairman Wu Fei: Focusing on OEM|ODM services & sharing production capacity -

2024-11-13

Customized Project | JinenU Solar 182-78N 630W Bifacial Module Project -

2024-11-11

Deputy Editor-in-chief of Qiushi (Seeking Truth) Magazine visited JinenU Solar Tai'an Base -

2024-11-01

Customized Project | JinenU Solar High-Efficiency, Large-Size 210R-66 Module Project -

2024-10-17

Customized Project | JinenU Solar 514MW 210N Topcon Project -

2024-10-12

JinenU Solar Zibo Production Base was honored as “Morning Star Factory” in Shandong Province -

2024-09-25

2-Year Anniversary of JinenU Solar Taizhou Base put into production -

2024-09-25

JinenU Solar Zibo Base was honored as one of the Top 100 Zibo Enterprise in Zibo City -

2024-09-09

Mr Wu Fei attended the Indonesia International Sustainability Forum 2024 (ISF) and Delivered Speech -

2024-09-06

JinenU Solar won "2024 Influential PV Intelligent Manufacturing Outstanding Employer Starlight Award" for the second consecutive year! -

2024-09-03

JinenU Solar Global Layout| Chairman Wu Fei attended the signing ceremony of PV supply chain cooperation in Indonesia -

2024-09-03

JinenU made its debut at The SmarterE South America 2024! -

2024-08-12

Customized Project | JinenU Solar 489MW 210-66 Topcon Project -

2024-07-25

Mr. Wu Fei: Focus on Mobilizing Demand and Optimizing the Ecosystem -

2024-07-25

Customized Project | JinenU Solar 134MW 210R-66 Module Project -

2024-07-01

JinenU Solar was selected as the director unit of All-China New Energy Chamber of Commerce -

2024-06-27

Intersolar Europe | JinenU Solar shines with its OEM|ODM Products and Services! -

2024-06-27

Mr. Wu Fei was invited to the 12th Global Green Energy and PV Finance Summit -

2024-06-27

20GW Focus on OEM! JinenU Solar Shines at Shanghai SNEC PV+ 2024 -

2024-06-03

The First TOPCon Module of the 3.6GW High-efficiency Module Project at Hexian Base Has Been Successfully Produced -

2024-06-03

The First TOPCon Module of the 3.6GW High-efficiency Module Project at Yuexi Base Has Been Successfully Produced -

2024-05-28

Customized Project | JinenU Solar 210-66N Large Size Module Project -

2024-05-16

Mr. Wu Fei, Chairman of JinenU Solar Group, Elected as Vice President of All-China New Energy Chamber of Commerce -

2024-05-16

Customized Project | JinenU Solar 1GW Large-Size Rectangular 182R, 210R Project -

2024-05-16

Customized Project | Trimming up to 39 times, JinenU Solar 200.6MW high-efficiency N-type and P-type module project -

2024-03-02

ODM|OEM mode shines in Tokyo! JinenU Solar makes appearance at PV EXPO 2024. -

2023-12-08

Customized Project | JinenU Solar Micro-rectangular 78.6MW High Efficiency Module Project -

2023-10-12

Customized Project|JinenU Solar 1.6MW All-Black TOPCon Module Customization Project

If You have ODM|OEM Requirement, Please Contact Us

Our professional team will provide the satisfactory customized production proposal for you